Modern retail supply chains are complex and operate at a massive global scale. Each day, millions of retail products are packaged and transported across thousands of geographical locations all across the globe. This level of complexity presents challenges for retailers in critical areas like:

- Procurement

- Product selection

- Customer fulfilment

- Inventory management

Among the complex challenges, retailers can no longer manually forecast market demand for their products, resulting in undersupplies and delayed deliveries. AI in supply chain management promises to overcome this challenge and much more. By leveraging attention-based neural networks, AI-enabled frameworks can significantly improve demand forecasting and business outcomes in the retail domain.

With AI-enabled models, modern retailers can transform demand forecasting by capturing complex time-bound dependencies and relationships between retail products and adapting their business to changing circumstances. Even with sparse data volumes, retail companies can build accurate predictive models for new products by replicating data patterns from similar products.

Introducing the placement optimization framework

In complex warehouses, a placement optimization framework provides retailers with a strategic approach to managing their inventory placement (or distribution) across locations. This framework aims for retail inventory optimization and performance by placing inventory items at the right location and right time.

This, in turn, can benefit retailers by minimizing their inventory costs and maintaining an optimum service level. What’s more impressive is that this framework is designed to operate at a significant global scale – with millions of retail products across thousands of warehouse facilities. Here are some of the key benefits of a Placement Optimization framework for retail companies:

- Cost savings: Retailers can leverage this framework to reduce costs accrued from product transportation, storage, and handling. Typically, transportation costs can be reduced by up to 20%.

- Adherence to service level agreements (SLAs): The placement optimization framework enables the retailer to abide by their customer SLA across the entire order fulfillment process, thus elevating customer satisfaction.

- Faster product deliveries: This framework can reduce delivery timelines by 15-30%, thus ensuring timely deliveries.

- Constraint satisfaction: The placement optimization framework accounts for any supply chain constraints like capacity optimization, safety stock, and operational constraints.

- Market adaptability: With this framework, retailers are better positioned to respond dynamically to any demand or supply fluctuations and real-world conditions.

How does the placement optimization framework work?

Besides demand forecasting, the placement optimization framework is also effective at retail inventory optimization across the retail distribution chain. Powered by AI technology, this framework can balance global supply chain efficiency with local responsiveness. This ensures that retailers can maintain an optimum stock level of retail products at the right location and time.

How does this AI-enabled placement optimization framework perform? Here are some of the techniques used in this framework:

-

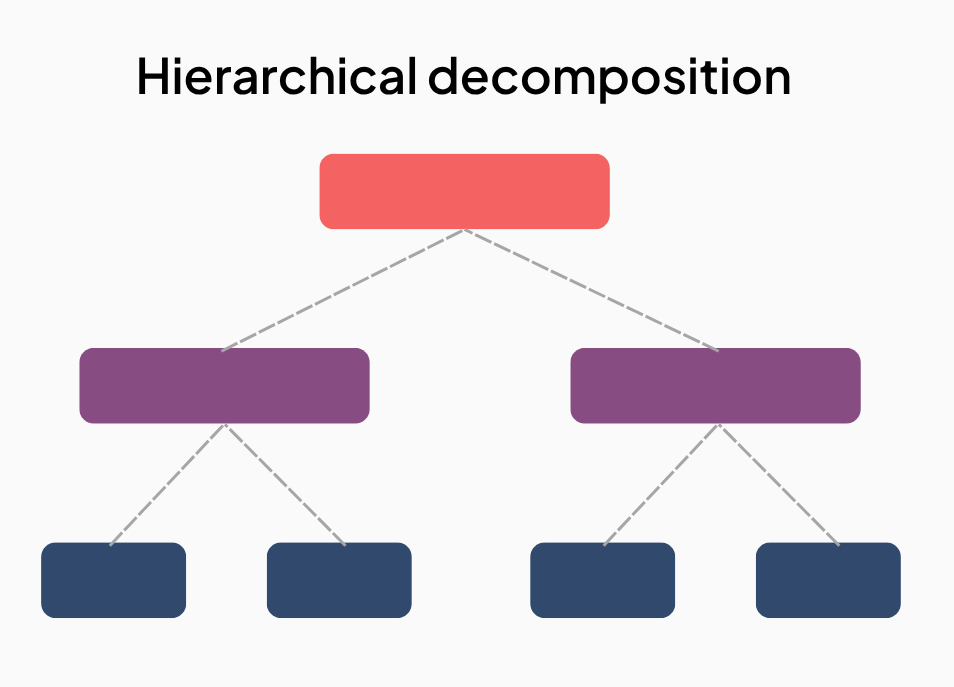

Hierarchical decomposition

This method is used to break down a major inventory placement problem into smaller manageable hierarchical components. This approach helps in addressing problems at multiple levels, which is useful in the case of large supply chain networks.

Here’s an example of how a grocery retailer can deploy this technique to place fresh produce across 800 stores. Listed below are some of their business benefits:

- 24% reduction in spoilage of perishable items.

- 8% reduction in transportation costs.

- Improvement of in-stock rate of produce items from 92% to 97%.

-

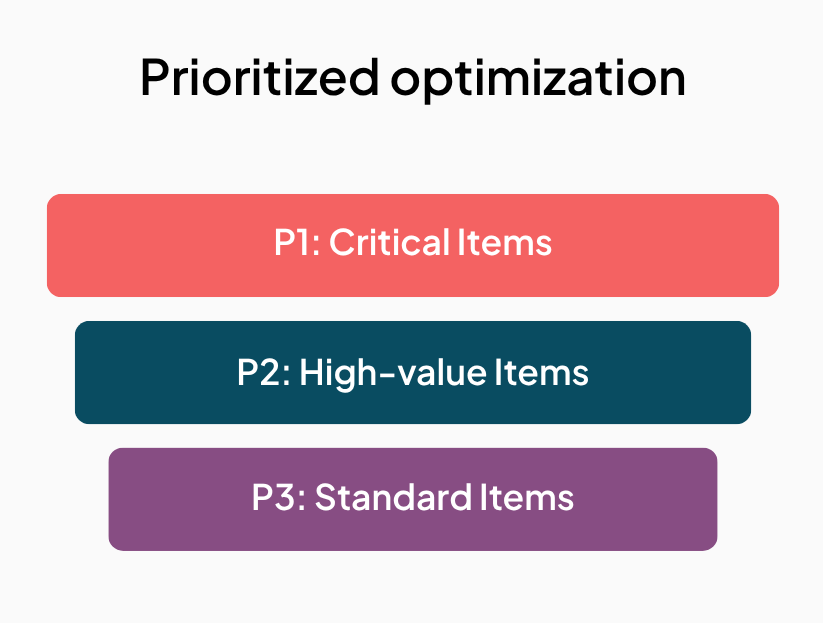

Prioritized optimization

With this method, retailers can allocate inventory based on defined business priorities and the criticality of the item. This method ensures that the most important product (or inventory item) is allocated placement on priority.

Here’s an example of how an automotive parts distributor manages over 30,000 SKUs using prioritized optimization. Listed below are some of their business benefits:

- 99% improvement in service level for safety-sensitive auto components – an increase from 96.4% previously.

- Accessibility to 85% of high-priority components in a 2-hour delivery window – up from 72% previously.

-

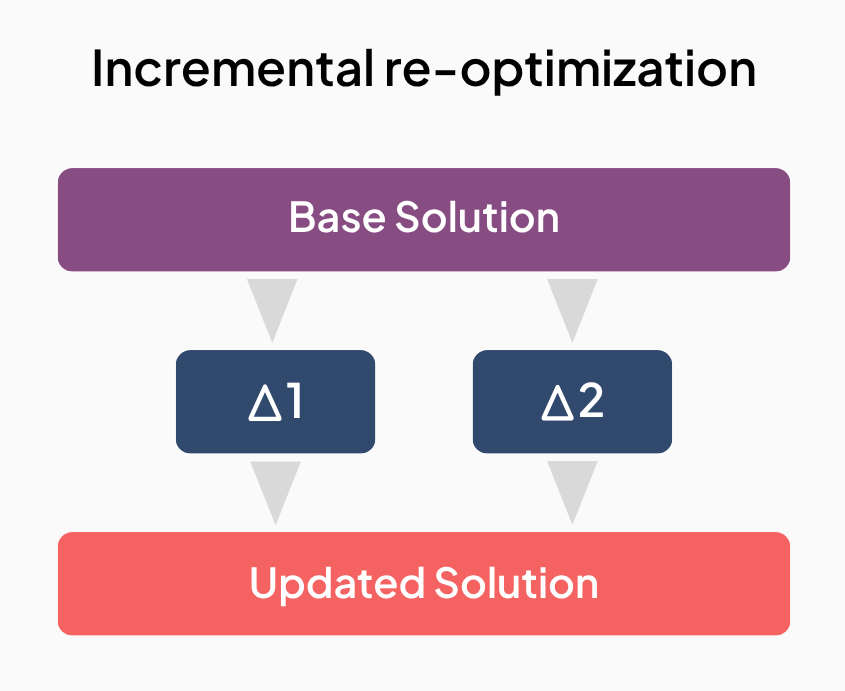

Incremental re-optimization

This method does not address the supply chain network challenges from scratch, but makes incremental updates for any change in conditions. This method is effective for adjusting existing inventory placements and improving quality while reducing computational overhead.

Here’s an example of how a fashion retailer (with regular launches of new fashion products) can deploy this technique to update their inventory placement strategies. Listed below are some of their business benefits:

- Reduction in optimization runtime from 4.5 hours every week to just 8 minutes.

- Maintaining the solution quality inside 0.2% of a full re-optimization.

Conclusion

Considering the growing uncertainties in the retail inventory management domain, companies can realize tangible benefits in their supply chains by adopting AI-enabled inventory placement solutions. Some of these benefits include:

- Up to 25% reduction in excessive inventory.

- High service levels at 99.5%.

- Substantial reduction in inventory carrying costs.

Besides the financial benefits, retailers can use AI-powered tools to improve their demand forecasting and reduce their working capital requirements. At Onix, we focus on simplifying our AI-driven solutions for the benefit of our global retail clientele. Our complete range of cloud retail solutions is designed to address the industry-specific challenges of our clients.

Are you looking for an AI-powered retail solution for your supply chain complexities? Contact us today with your requirements.